DIN 1.2080 also know as X210Cr12 steel ,it belongs to standard DIN EN ISO 4957. It is a widely used cold work steel with high strength, good hardenability and good wear resistance. It mainly used for cold punching dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, stamping dies, thread rolling dies, drawing dies and thread rolling dies that bear small impact loads and require high wear resistance.

DIN 1.2080 Introduction

DIN 1.2080 steel is a high-carbon, high-chromium ledeburite steel . This steel has good hardenability, wear resistance, and hot workability. However , the composition don’t add VCarbides are well distributed in the steel and can be used for manufacturing Various cold work dies with complex shapes and heavy working conditions. Such as cold die punches, thread rolling dies, wire drawing dies, material dies, metallurgical powder dies, woodworking cutting tools, cold cutting scissors, drill sleeves and gauges.

DIN 1.2080 Steel and its Equivalent Chemical composition :(%)

| ASTM A681 | C | Mn | P | S | Si | Cr | V | T | Mo | |||||||

| D3 | 2.00 | 2.35 | 0.10 | 0.60 | Max 0.030 | Max 0.030 | 0.10 | 0.60 | 11.00 | 13.50 | . . . | 1.10 | . . . | 1.00 | . . . | . . . |

| DIN ISO 4957 | C | Mn | P | S | Si | Cr | V | T | Mo | Ni | ||||||

| 1.2080/X210Cr12 | 1.90 | 2.20 | 0.20 | 0.60 | Max 0.030 | Max 0.030 | 0.10 | 0.60 | 11.00 | 13.00 | – | – | – | – | – | – |

| JIS G4404 | C | Mn | P | S | Si | Cr | V | T | Mo | Ni | ||||||

| SKD1 | 1.90 | 2.20 | 0.20 | 0.60 | Max 0.030 | Max 0.030 | 0.10 | 0.60 | 11.00 | 13.00 | – | – | – | – | – | – |

Characteristic:

1. Vacuum degassing and refining treatment make the steel pure.

2. Spheroidizing annealing and softening treatment, good cutting performance.

3. The strengthening element vanadium and molybdenum are specially added to provide extremely excellent wear resistance.

Application:

Application:

1. Thickness no more than 2MM thin plate, high-efficiency blanking die, punching die and stamping die.

2. Various scissors, inlaid blades, woodworking blades.

3. Thread rolling die and wear-resistant slider.

4. Cold heading mold, thermosetting resin molding mold.

5. Stretch forming mold and cold extrusion mold.

Mechanical Properties:

| Mechanical Properties | Metric | Imperial |

|---|---|---|

| Izod impact unnotched | 28.0 J | 20.7 ft-lb |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30457 ksi |

Physical Properties:

| Physical Properties | Metric | Imperial |

|---|---|---|

| Density | 7.7 x 1000 kg/m3 | 0.278 lb/in3 |

| Melting Point | 1421°C | 2590°F |

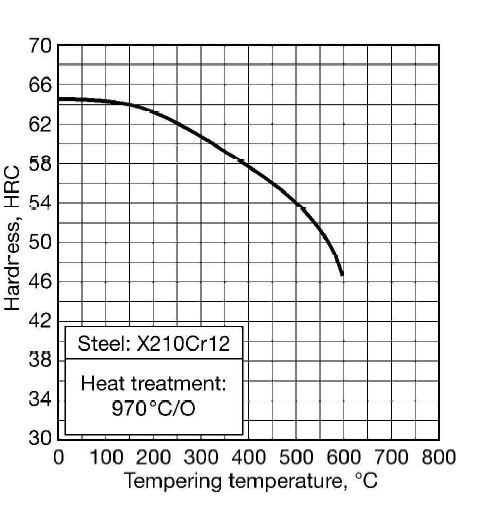

DIN 1.2080 Steel Heat treatment :

| Temperature | Cooling | Hardness | |

| Soft annealing | 800 – 840 °C | Furnace | Max 255 HB |

| Stress relief annealing | 600 – 650°C | Furnace | |

| Hardening | 950 – 980°C | oil, pressure gas (N2), air or hot bath 500 – 550°C | see tempering diagram |

Delivery status:

The steel is delivered in an annealed state.

Conclusion:

DIN 1.2080 mold steel is also one of the internationally used cold work mold steels, but has recently been gradually replaced by better steel types such as Cr12MoV, Cr12Mo1V1 or matrix steel. It is mainly used for cold stamping die working parts that require high wear resistance and small impact load (punch and concave dies), cold extrusion die concave dies, etc. Although its use is subject to certain restrictions due to its obvious advantages and disadvantages, it is still used in some specific areas are still irreplaceable.

Want to know more about the DIN 1.2080 ( X210Cr12 ) /D3/SKD1 steel details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365