1.3343 steel is a high-toughness high-speed steel containing a high proportion of tungsten and has the characteristics of high wear resistance and high efficiency. Grade 1.3343 is the HSS type steel. HSS refers to high speed steel grade. The grade is defined in the ISO 4957.This kind of steel has excellent comprehensive mechanical properties and good cutting performance. Therefore, it is widely used in various tool and mold manufacturing fields.

1.3343 is supplied with a hardness of 230HBS and can reach 64HRC after quenching and tempering.

Chemical composition and its equivalents

| ASTM A600 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| M2 regular C | 0.78 | 0.88 | 0.15 | 0.40 | 0.03 | 0.03 | 0.20 | 0.45 | 3.75 | 4.50 | 1.75 | 2.20 | 4.50 | 5.50 | 5.50 | 6.75 |

| DIN ISO 4957 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| 1.3343/HS6-5-2C | 0.86 | 0.94 | … | … | … | … | … | 0.45 | 3.80 | 4.50 | 1.70 | 2.10 | 4.70 | 5.20 | 5.90 | 6.70 |

| JIS G4403 | C | Mn | P | S | Si | Cr | V | Mo | W | |||||||

| SKH51 | 0.80 | 0.88 | … | 0.40 | 0.03 | 0.03 | … | 0.45 | 3.80 | 4.50 | 1.70 | 2.10 | 4.70 | 5.20 | 5.90 | 6.70 |

Physical properties of 1.3343

| Density | 0.294 lb/in3 (8138 kg/m3) |

| Specific Gravity | 8.15 |

| Modulus of Elasticity | 0.294 lb/in3 (8138 kg/m3) |

| Thermal conductivity | 24 Btu/ft/hr/°F 41.5 W/m/°K |

| Machinability | 65% of a 1% carbon steel |

Mechanical properties of 1.3343

| Mechanical properties | Metric | Imperial |

| Hardness, Rockwell C (tempered at 1150°F, quenched at 2200°F) | 62 | 62 |

| Hardness, Rockwell C (as hardened, quenched at 2200°F) | 65 | 65 |

| Compressive yield strength (when tempered at 300°F) | 3250 MPa | 471000 psi |

| Izod impact unnotched (when tempered at 300°F) | 67 J | 49.4 ft-lb |

| Abrasion (loss in mm3, as-hardened; ASTM G65) | 25.8 | 25.8 |

| Abrasion (loss in mm3, tempered at 1275°F; ASTM G65) | 77.7 | 77.7 |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

Heat treatment about DIN 1.3343 steel

Heat treatment about DIN 1.3343 steel

Soft annealing:

820 to 850 °C for about 2 to 5 hours

slow controlled cooling of 10 to 20 °C per hour to about 550 °C;

further cooling in air. Maximum 270 HB

Hardening:

1190 – 1230 °C

Quenching in oil/compressed gas/air/hot bath

Min: 64 HRC

Tempering:

Min560 °C

Slow heating to tempering temperature (to avoid forming of cracks)

immediately after hardening;

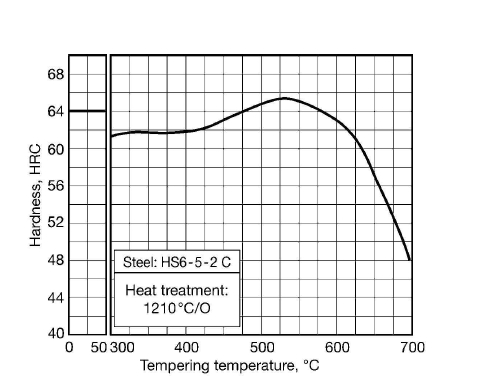

Hardneess -tempering temperature -curves for 1.3343/H6-5-2C steel

Characteristic of 1.3343 HSS steel

- High hardness, MinHRC64 after final heat treatment,

- The carbides are fine and evenly distributed and have good wear resistance.

- Good thermoplasticity.

Application of 1.3343 HSS steel

- Particularly suitable for cold rutting dies and extrusion tools.

- General toughness precision wear-resistant hardware cold stamping dies, cold extrusion blades, punches and dies.

- Suitable for processing into various types of drill bits, milling cutters and other cutting tools.

- Particularly suitable for tools subjected to vibration and impact loads.

Name: Joann

Name: Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365