1045 and 4140 steel are two of the most common materials used in industrial construction.As we know 1045 is a carbon steel and 4140 steel is a alloy steel.But what is the mainly difference of these two steel ? I introduce in this artical, let’s check.

Composition and Properties

1045 Steel: This is a medium carbon steel, it contain 0.43%-0.50% carbon with a better strength, toughness, and wear resistance. Due to the proper carbon content, it’s relatively easy to machine and weld. It’s usually used in high strength and moderate wear resistance situation.

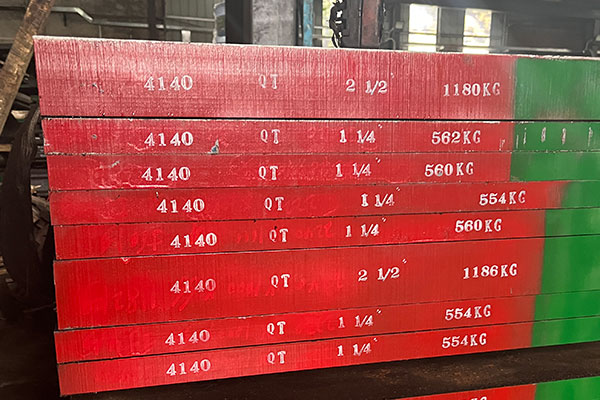

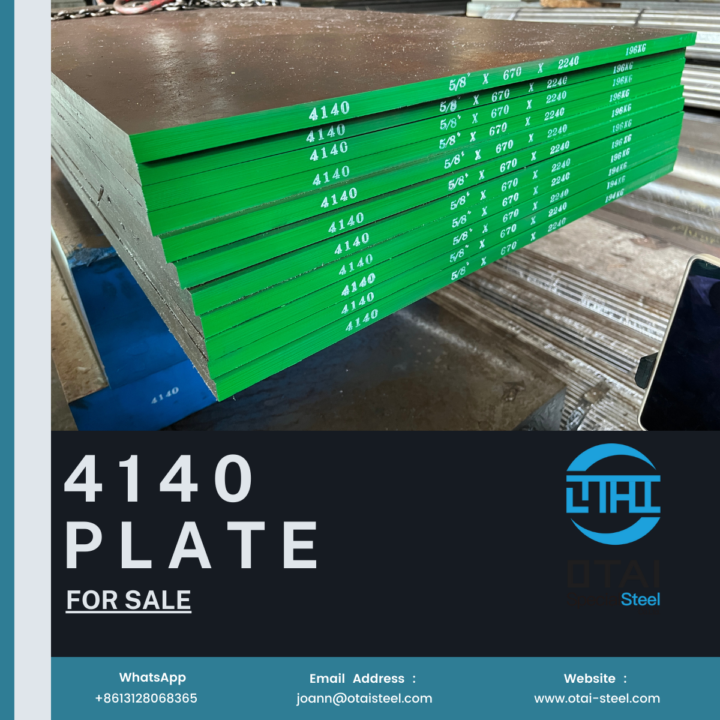

4140 Steel: We also introduce in last artical . 4140 steel also known as chromoly steel, 4140 contains 0.38%-0.43% carbon along with other alloying elements like chromium and molybdenum. These chermical composition provides excellent strength, hardness, and fatigue resistance. Therefore it’s particularly well-suited for applications that require high tensile strength and good impact resistance.

| C | Si | Mn | S | P | Cr | Mo | Ni | |

| 1045 | 0.43-0.50 | / | 0.60-0.90 | ≤0.050 | ≤0.040 | / | / | / |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.035 | 0.80-1.10 | 0.15-0.25 |

Strength and Hardness

One of the most significant differences between 1045 and 4140 steel lies in their strength and hardness properties. 4140 steel, with its higher carbon content and alloying elements, offers superior strength and hardness compared to 1045. This makes it a better choice to applicate in high tensile strength and resistance to wear and abrasion.

Machinability

1045 steel with a good machinability. It can be easily cut, turned, drilled, and milled using conventional machining techniques. On the other hand, 4140 steel, while still machinable, requires a long time machine efficiently and specialized tools due to its higher hardness.

Weldability

Both 1045 and 4140 steel can be welded, but 1045 is generally considered to have better weldability. Its lower carbon content reduces the risk of cracking during welding. 4140 steel, with its higher carbon content and alloying elements, requires preheating and post-welding stress relief to minimize the risk of cracking.

Heat Treatment

Both steels reflect well to heat treatment, allowing for a wide range of hardness and strength levels to be achieved. This versatility makes them suitable for a variety of applications.

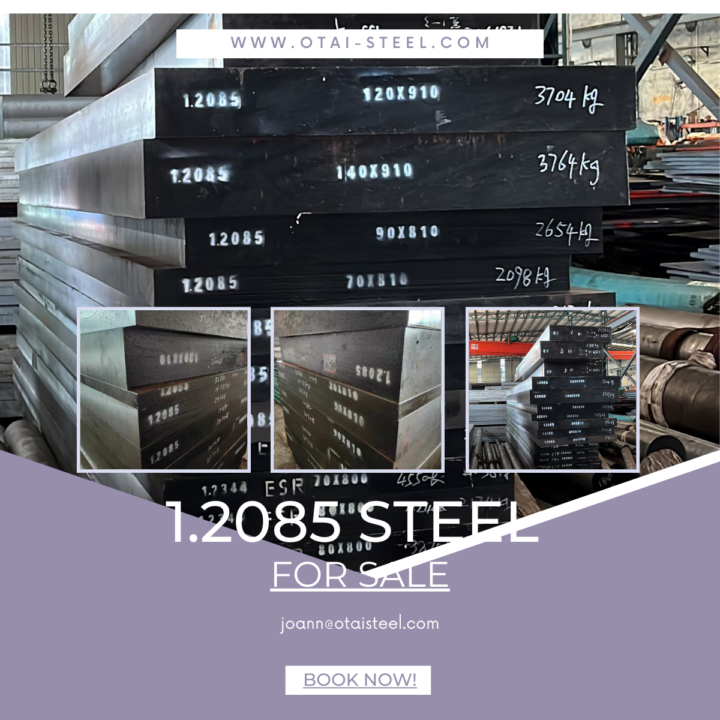

Otai stock 1045 and 4140 steel more than 3000 tons . If you have interest , you can visit our mainly website :http://www.otaisteel.com