34CrNiMo6/1.6582 alloy steel is high-strength engineering steel as per BS EN 10083-3:2006 . It is widely used in the manufacture of important parts such as engine camshafts and connecting rods due to its excellent comprehensive mechanical properties.

What is 34CrNiMo6/1.6582 alloy steel ? Below let’s explain it from its chemical composition , properties , application etc aspect.

Chemical composition of 34CrNiMo6/1.6582 alloy steel and its equivalent steel

| BS EN 10083 – 3:2006 | 34CrNiMo6 /1.6582 |

C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.025 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| BS EN 10250-3:2000 | C | Mn | Si | P | S | Cr | Mo | Ni | |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.035 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| ASTM A29: 2004 | 4337 | C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.40 | 0.6-0.8 | 0.20-0.35 | 0.035 max | 0.040 max | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

Mechanical Properties of 34CrNiMo6/1.6582 alloy steel

Below is the mechanical Properties after QT in room temperture

| Properties | < 16 | >16 – 40 | >40 – 100 | >100 – 160 | >160 – 250 |

| Thickness t [mm] | < 8 | 8<t<20 | 20<t<60 | 60<t<100 | 100<t<160 |

| Yield strength Re [N/mm²] | min. 1000 | min. 900 | min. 800 | min. 700 | min. 600 |

| Tensile strength Rm [N/mm2] | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A [%] | min. 9 | min. 10 | min. 11 | min. 12 | min. 13 |

| Reduction of area Z [%] | min. 40 | min. 45 | min. 50 | min. 55 | min. 55 |

| Toughness CVN [J] | min. 35 | min. 45 | min. 45 | min. 45 | min. 45 |

Heat treatment of 34CrNiMo6/1.6582 alloy steel

| Grade | Quenching | Tempering | Annealing | Normalizing | |||

| Temperture(°C) | Media | Time (mins) | Temperture(°C) | Time (mins) | |||

| 34CrNiMo6/1.6582 | 830-860 | Oil or Water | 30 | 540-660 | 60 | 850-880°C and then slowly cool in the furnace to below 600°C for annealing. | Heat the material to around 870-900°C and then cool in still air |

The heat treatment of 34CrNiMo6 typically involves processes to achieve desired mechanical properties.

It’s essential to follow precise temperature and cooling rate guidelines during each step to achieve the desired microstructure and mechanical properties in the final product. Additionally, specific requirements for hardness, strength, and toughness will dictate the exact parameters of the heat treatment process. Consulting material specifications and/or a metallurgical engineer is recommended for precise heat treatment instructions.

Characteristic of 34CrNiMo6 steel

High Strength: 34CrNiMo6 has excellent high strength and is able to withstand high load and high stress conditions.

High toughness: The alloy has good toughness and is able to maintain structural integrity under high loads and avoid easy fracture.

Wear Resistance: Due to its alloy composition, 34CrNiMo6 has good wear resistance and is suitable for applications in high friction and high wear environments.

High-temperature properties: The alloy maintains a certain hardness and strength in high-temperature environments, making it suitable for high-temperature applications.

Application of 34CrNiMo6 steel

34CrNiMo6 material is widely used in manufacturing various high-load and high-wear parts, including but not limited to:

Gears and drive shafts: Used in automobiles, industrial machinery, aerospace and heavy equipment, etc.

Bearings: Bearings used to support rotating parts, such as engines and machinery.

Forgings and forging dies: Used to make forgings and forging dies, such as hammer heads and dies.

Oil and Gas Extraction Equipment: Used in the manufacture of drill bits, drill pipe and parts for oilfield equipment.

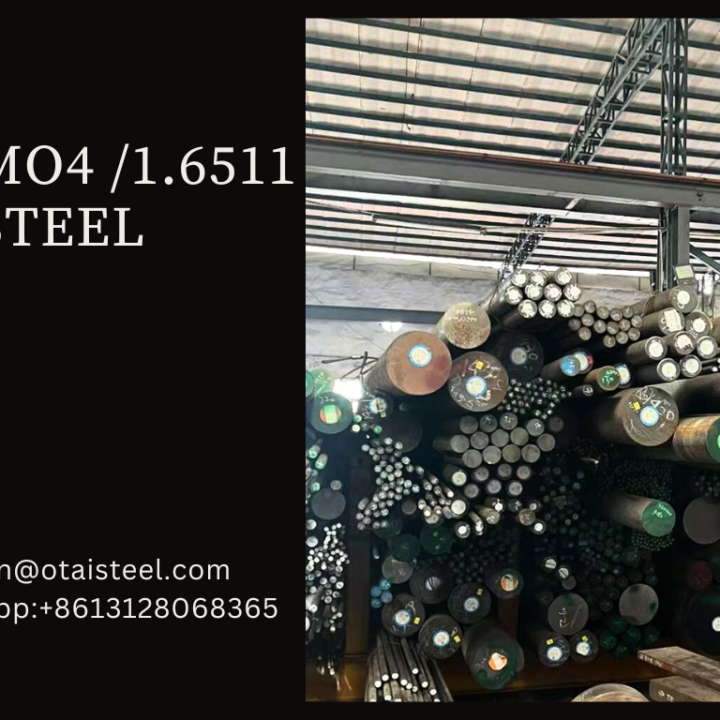

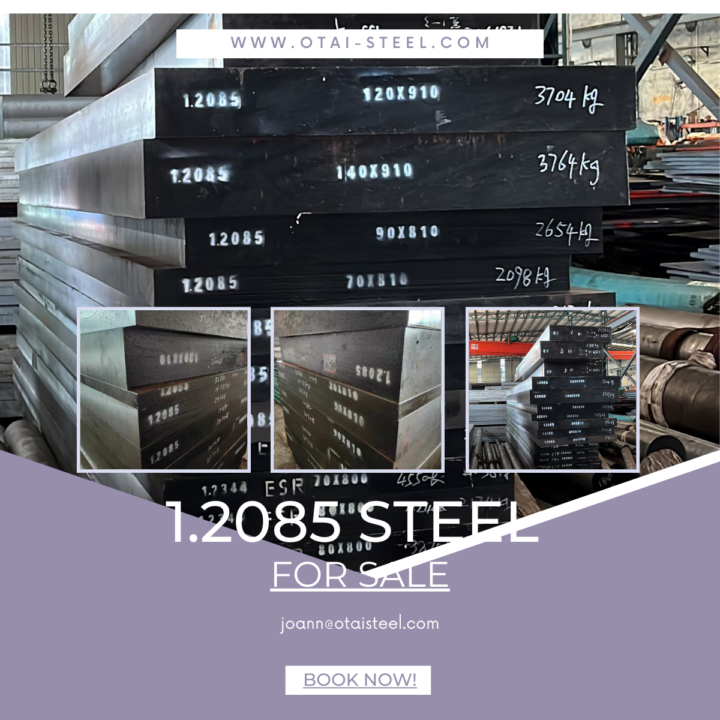

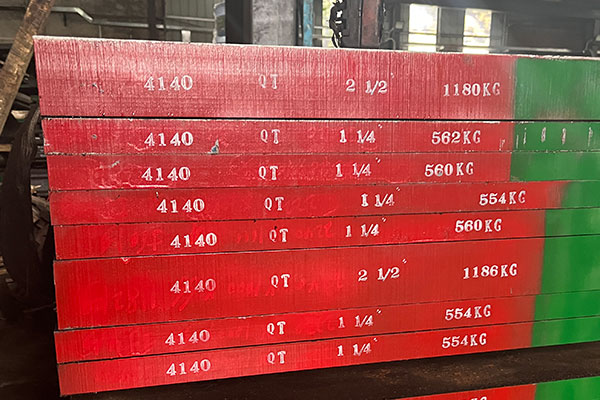

Stock and price

Otai stock 34CrNiMo6 more than 1000tons , size from 12mm to 600mm . If you have any interest , please contact :

Name: Joann

Name: Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365