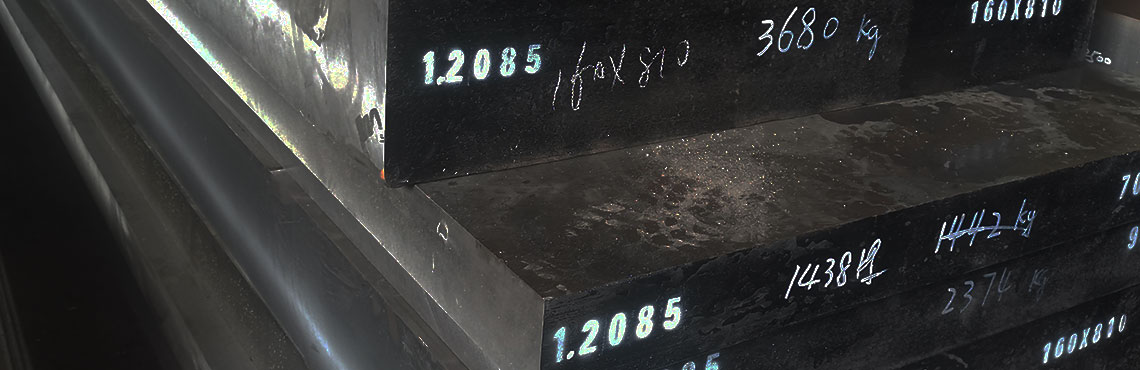

When it comes to steel, various grades and equivalents exist to serve specific purposes in industries ranging from construction to manufacturing, one such steel variant that has gained recognition is 1.2085 steel and its equivalents. In this article, we will delve into the properties, applications, and equivalents of 1.2085 steel, shedding light on its importance in various industries.

1. What is 1.2085 Steel?

1.2085 steel is a widely use tool steel known for its exceptional durability, hardness, and wear resistance . It belongs to the family of chromium-molybdenum steels, which well know for their excellent machinability and robust performance in demanding environments.

2. Properties of 1.2085 Steel

2. Properties of 1.2085 Steel

– Hardness: One of the standout features of 1.2085 steel is its high hardness level. This property makes it suitable for applications where wear resistance is crucial.

– Toughness: Despite its hardness, 1.2085 steel also exhibits good toughness, providing a balanced combination of strength and durability.

– Corrosion Resistance: Thanks to its chromium content, 1.2085 steel offers resistance against corrosion and oxidation, ensuring a prolonged lifespan in various environments.

3. Applications of 1.2085 Steel

1.2085 steel finds its applications in several industries due to its exceptional properties:

– Molds and Dies: It commonly use in the production of molds and dies for plastic injection molding and die casting processes. Its high hardness and wear resistance ensure a longer tool life.

– Cutting Tools: The durability and toughness of 1.2085 steel make it an excellent choice for manufacturing cutting tools such as knives, shears, and blades.

– Industrial Components: It is also utilize in the production of various industrial components, including shafts, gears, and other precision parts.

4. 1.2085 Steel Equivalents

4. 1.2085 Steel Equivalents

Understanding the equivalents of 1.2085 steel is crucial for selecting the right material for a specific application. Some of the notable equivalents include:

– DIN 1.2085: This is the German standard equivalent for 1.2085 steel. It shares similar chemical composition and properties, making it a suitable alternative.

– AISI 420: This is an American equivalent to 1.2085 steel. It is widely used in applications where corrosion resistance and high hardness are critical factors.

– GB 4Cr13: In the Chinese steel grading system, 4Cr13 is the equivalent of 1.2085 steel. It is recognized for its similar properties and performance.

Conclusion

In conclusion, 1.2085 steel and its equivalents are pivotal materials in various industries due to their exceptional properties. From molds and dies to cutting tools, this steel variant plays a vital role in ensuring the efficiency and longevity of numerous applications. Understanding its properties and equivalents empowers industries to make informed decisions when selecting materials for specific tasks.

FAQs

1. Is 1.2085 steel suitable for high-temperature applications?

While 1.2085 steel exhibits good heat resistance, it is not recommended for prolonged exposure to extremely high temperatures. For applications involving extreme heat, specialized heat-resistant steels may be more appropriate.

2. Can 1.2085 steel be welded?

Yes, 1.2085 steel can weld using conventional welding techniques. However, it’s essential to use appropriate preheating and post-welding procedures to maintain its properties.

3. Are there specific heat treatment processes recommended for 1.2085 steel?

Yes, common heat treatment methods for 1.2085 steel include quenching and tempering. These processes help optimize its hardness, toughness, and overall performance for specific applications.

4. What industries commonly use 1.2085 steel?

1.2085 steel is prevalent in industries such as plastic injection molding, die casting, automotive manufacturing, and general tool and die production.

5. How does 1.2085 steel compare to other tool steels in terms of performance?

1.2085 steel balance combination of hardness, toughness, and corrosion resistance, making it a competitive choice in various applications.

Want to know more about the details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365