AISI 4340 steel is a medium-carbon low-alloy high-strength steel and a typical representative of low-alloy ultra-high-strength steel. It has good hardenability, well-matched strength and toughness, high fatigue strength and low notch sensitivity, high low-temperature impact toughness, and no obvious temper brittleness.

AISI 4340 steel standard

The execution standard for 4340 steel is ASTM A29/A29M-04

Chemical composition of AISI 4340 steel and equilvalent grade

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A29 | 4340 | 0.38-0.43 | 0.60-0.80 | 0.035 | 0.040 | 0.15-0.35 | 1.65-2.00 | 0.70-0.90 | 0.20-0.30 |

| EN 10250 | 36CrNiMo4/ 1.6511 |

0.32-0.40 | 0.50-0.80 | 0.035 | 0.035 | ≦0.40 | 0.90-1.20 | 0.90-1.2 | 0.15-0.30 |

| BS 970 | EN24/ 817M40 | 0.36-0.44 | 0.45-0.70 | 0.035 | 0.040 | 0.1-0.40 | 1.3-1.7 | 1.00-1.40 | 0.20-0.35 |

| JIS G4103 | SNCM 439/ SNCM8 | 0.36-0.43 | 0.60-0.90 | 0.030 | 0.030 | 0.15-0.35 | 1.60-2.00 | 0.60-1.00 | 0.15-0.30 |

Heat treatmemt

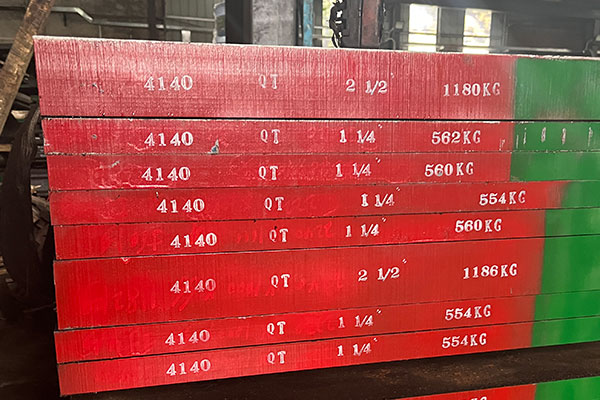

Quenching:AISI 4340 alloy steel heat treat at 830°C (1525°F) followed by quenching in oil.

Forging:AISI 4340 alloy steel is forged at 427 to 1233°C (1800 to 2250°F).

Cold Working:AISI 4340 alloy steel can be cold worked using all conventional methods in the annealed condition. It has high ductility.

Annealing:AISI 4340 alloy steel is annealed at 844°C (1550°F) followed by cooling the furnace.

Tempering:AISI 4340 alloy steel should be in the heat treated or normalized and heat treated condition before tempering. The tempering temperature for depends upon the strength level desired. For strength levels in the 260 – 280 ksi range temper at 232°C (450 F). For strength in the 125 – 200 ksi range temper at 510°C (950 F). And don’t temper the 4340 steels if it is in the 220 – 260 ksi strength range as tempering can result in degradation of impact resistance for this level of strength.

Hardening:AISI 4340 alloy steel can be hardened by cold working or heat treatment.

Physical properties

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm3 | 0.284 lb/in³ |

| Melting point | 1427°C | 2600°F |

Mechanical Properties

| Mechanical Property Designation | T | *U | V | W | X | Y | Z | |||

| Limited Ruling Section (mm) | 150 | 100 | 63 | 30 | 30 | 30 | 30 | |||

| Tensile Strength (Min.) | 850 | 930 | 1000 | 1080 | 1150 | 1230 | 1550 | |||

| Tensile Strength (Max.) | 1000 | 1080 | 1150 | 1230 | 1300 | 1380 | ||||

| 0.2% Proof Stress Mpa (Min.) | 665 | 740 | 835 | 925 | 1005 | 1080 | 1125 | |||

| Elongation on 5.65√S0 % | 13 | 12 | 12 | 11 | 10 | 10 | 5 | |||

| Izod Impact J (Min.) | 54 | 47 | 47 | 41 | 34 | 24 | 10 | |||

| Charpy Impact J (min.) | 50 | 42 | 42 | 35 | 28 | 20 | 9 | |||

| Brinell Hardness HB (Min.) | 248 | 269 | 293 | 311 | 341 | 363 | 444 | |||

| Brinell Hardness HB (Max.) | 302 | 331 | 352 | 375 | 401 | 429 | ||||

| *Material stocked generally in condition U.

Check test certificate if critical for end use.

|

||||||||||

AISI 4340 Steel Application

Due to its high strength, toughness, and weldability. It finds applications in various industries, including:

Due to its high strength, toughness, and weldability. It finds applications in various industries, including:

- Aerospace: Components such as landing gear, engine parts, and structural components in aircraft.

- Automotive: Crankshafts, axle shafts, gears, and other critical components in high-performance engines and transmissions.

- Oil and Gas: Drill collars, drill rods, and other downhole drilling equipment require materials with high strength and toughness to withstand harsh drilling conditions.

- Marine: Components in marine environments, such as propeller shafts and crankshafts for ship engines.

- Defense and Military: Applications include gun barrels, gears, and other components in firearms and military vehicles .

- Industrial Machinery: Various industrial machinery components, including gears, shafts, and crankshafts, use 4340 steel due to its high strength and fatigue resistance.

- Tool and Die Making: Dies, punches, and other tooling components benefit from the wear resistance and toughness of 4340 steel in applications such as stamping and forming.

- Power Generation: Components in power generation equipment, such as turbine shafts and gears, utilize 4340 steel for its strength and resistance to fatigue and wear.

- Heavy Equipment: Components in heavy machinery and equipment, such as axles, gears, and crankshafts in construction and mining equipment, rely on the high strength and durability of 4340 steel.

- Racing and Motorsports: High-performance racing cars and motorcycles often use 4340 steel for critical components like crankshafts and connecting rods due to its strength and fatigue resistance.

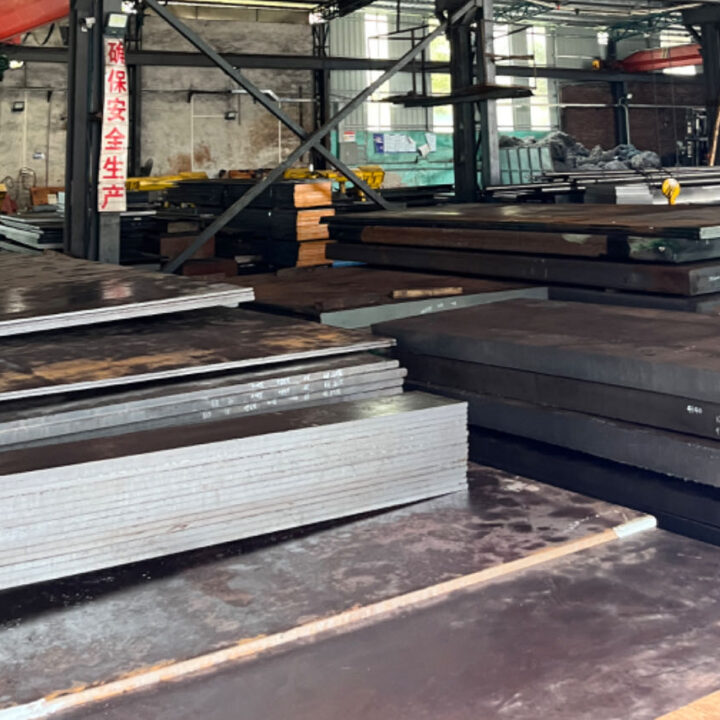

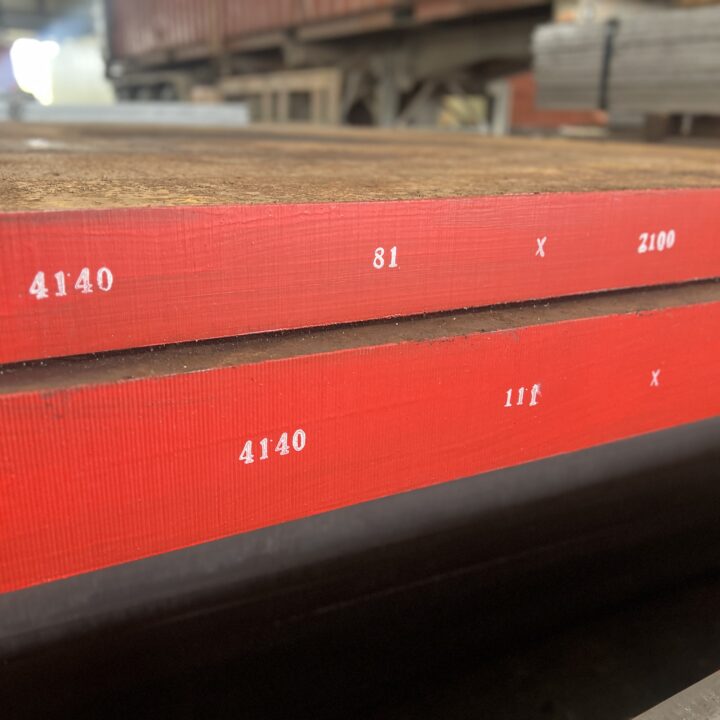

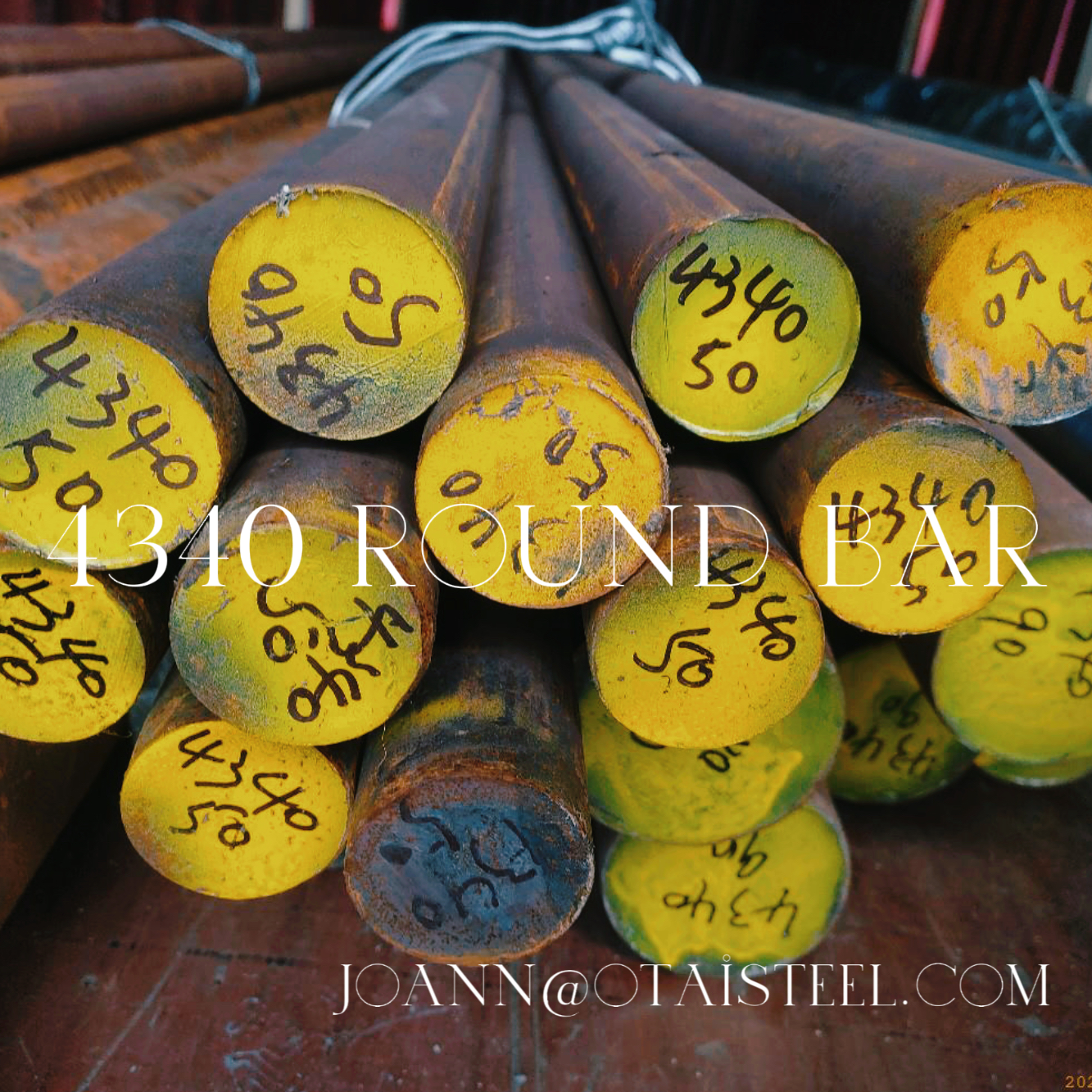

Want to know more about the AISI 4340 steel details and stock list ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365