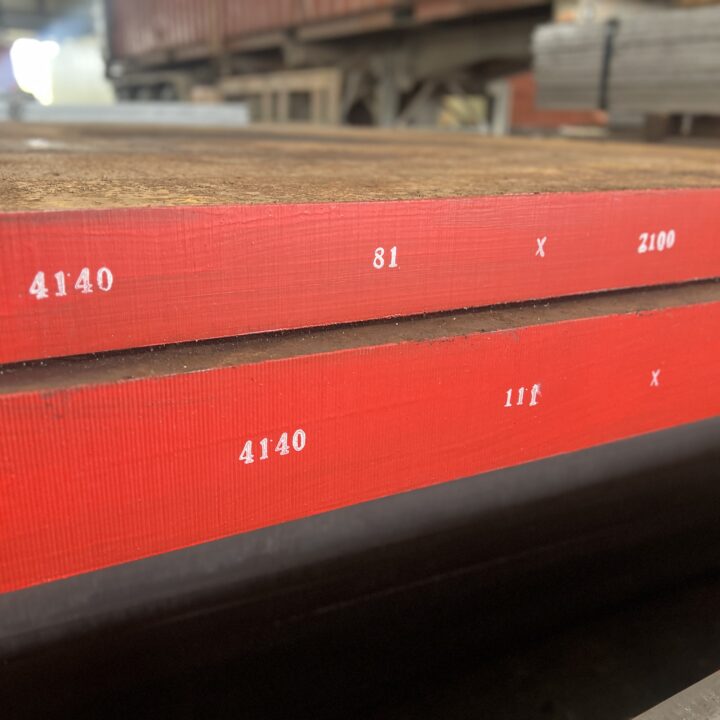

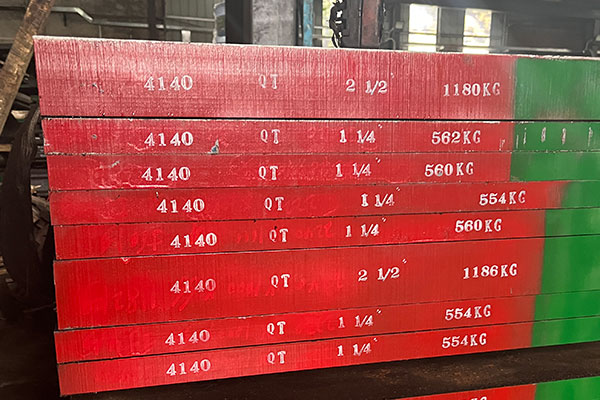

When it talk to widely used and reliable steel, AISI/SAE 4140 steel should be a top contender. This alloy steel is known for its good strength, long lasting, and adaptability across various industries. In this article, we’ll analyze the details of AISI/SAE 4140 steel, exploring its properties, applications, and the value it brings to engineering and manufacturing processes.

The Basics of AISI/SAE 4140 Steel

AISI/SAE 4140 is a chromium-molybdenum steel wide know for its high tensile strength and excellent toughness. The ’41’ in its name means 0.41% carbon content, while the ’40’ for 0.4% molybdenum content.AISI means American Iron and Steel Institute and SAE means Society of Automotive Engineers , both are Steel Designation System.

Key Properties of AISI/SAE 4140

High Tensile Strength: AISI/SAE 4140 boasts impressive tensile strength, making it suitable for applications under high-stress conditions.

Good Fatigue Resistance: This steel exhibits excellent fatigue resistance, crucial for components subject to repetitive loading.

Impact Toughness: The combination of chromium and molybdenum enhances its toughness, allowing it to withstand sudden impacts without deformation or fracture.

Machinability: AISI/SAE 4140 can machine relatively easily, making it a preferred choice in manufacturing processes.

Heat Treatability: It responds well to heat treatment, allowing for a wide range of hardness levels to achieve.

Applications o

Applications o

Automotive Industry

In the automotive sector, AISI/SAE 4140 is widely used for critical components such as axles, crankshafts, and gears. Its high strength and fatigue resistance make it ideal for withstanding the demands of vehicle operation.

Aerospace Engineering

4140 applicate in aerospace where request safety and reliability , AISI/SAE 4140 finds use in components like landing gear parts, structural elements, and engine components. Its combination of strength and toughness enables it to withstand the harsh aerospace environment

Oil and Gas Industry

The harsh environments of the oil and gas industry require materials that can withstand extreme conditions. AISI/SAE 4140 is a favored choice for components like drilling tools, wellhead equipment, and downhole components due to its excellent mechanical properties.

Construction and Heavy Equipment

In construction and heavy equipment manufacturing, AISI/SAE 4140 use for critical load-bearing components like gears, shafts, and connecting rods. Its high strength-to-weight ratio and durability make it an indispensable material in this industry.

Advantages

Versatility: Its adaptability across various industries and applications make it a versatile material choice.

Cost-Effective: Despite its exceptional properties, AISI/SAE 4140 with competitive price, offering a cost-effective solution for many engineering projects.

Longevity: Components made from AISI/SAE 4140 tend to have a longer service life, reducing maintenance and replacement costs.

Machinability: Its machinability ensures that manufacturing processes are efficient and cost-effective.

Conclusion

AISI/SAE 4140 steel is a powerhouse material in the engineering world, prized for its exceptional properties and versatility across various industries. Its high tensile strength, excellent fatigue resistance, and heat treatability make it a top choice for critical applications. From automotive to aerospace, oil and gas to construction, AISI/SAE 4140 plays a crucial role in shaping modern engineering solutions.

FAQs

1. What does 4140 steel stand for?

AISI/SAE 4140 is a chromium-molybdenum steel known for its high tensile strength and toughness. The numbers in its name represent the carbon and molybdenum content, respectively.

2. How is 4140 steel used in the automotive industry?

AISI/SAE 4140 steel finds extensive use in the automotive sector for critical components like axles, crankshafts, and gears due to its high strength and fatigue resistance.

3. Can 4140 steel be heat-treated?

Yes, AISI/SAE 4140 steel responds well to heat treatment, allowing for a wide range of hardness levels to achieve, enhancing its versatility in various applications.

4. What are the advantages of using AISI/SAE 4140 steel in aerospace engineering?

In aerospace applications, AISI/SAE 4140’s combination of strength and toughness makes it ideal for components like landing gear parts, structural elements, and engine components, ensuring safety and reliability.

5. Is AISI/SAE 4140 steel cost-effective?

Despite its exceptional properties, AISI/SAE 4140 steel with competitive price, offering a cost-effective solution for many engineering projects, making it a popular choice across industries.