When we talk to choosing the right steel for mould making, the most important is consider the precision and performance . Two popular options of mould steel are 1.2311 and 1.2738 steel. In this article, we’ll analyzes from the chemical composition, physical properties and mechanical properties, price, and applications of these two steels , hope to help you make an informed decision.

Chemical Composition 1.2311 VS 1.2738 steel:

1.2311 and 1.2738 steel belong to the category of plastic mould steels and exhibit different chemical compositions that influence their properties.

| Grade | C | Si | Mn | S | P | Cr | Mo | Ni |

| 1.2738 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤0.030 | ≤0.030 | 1.80-2.10 | 0.15-0.25 | 0.90-1.20 |

| 1.2311 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤0.035 | ≤0.035 | 1.80-2.10 | 0.15-0.25 | / |

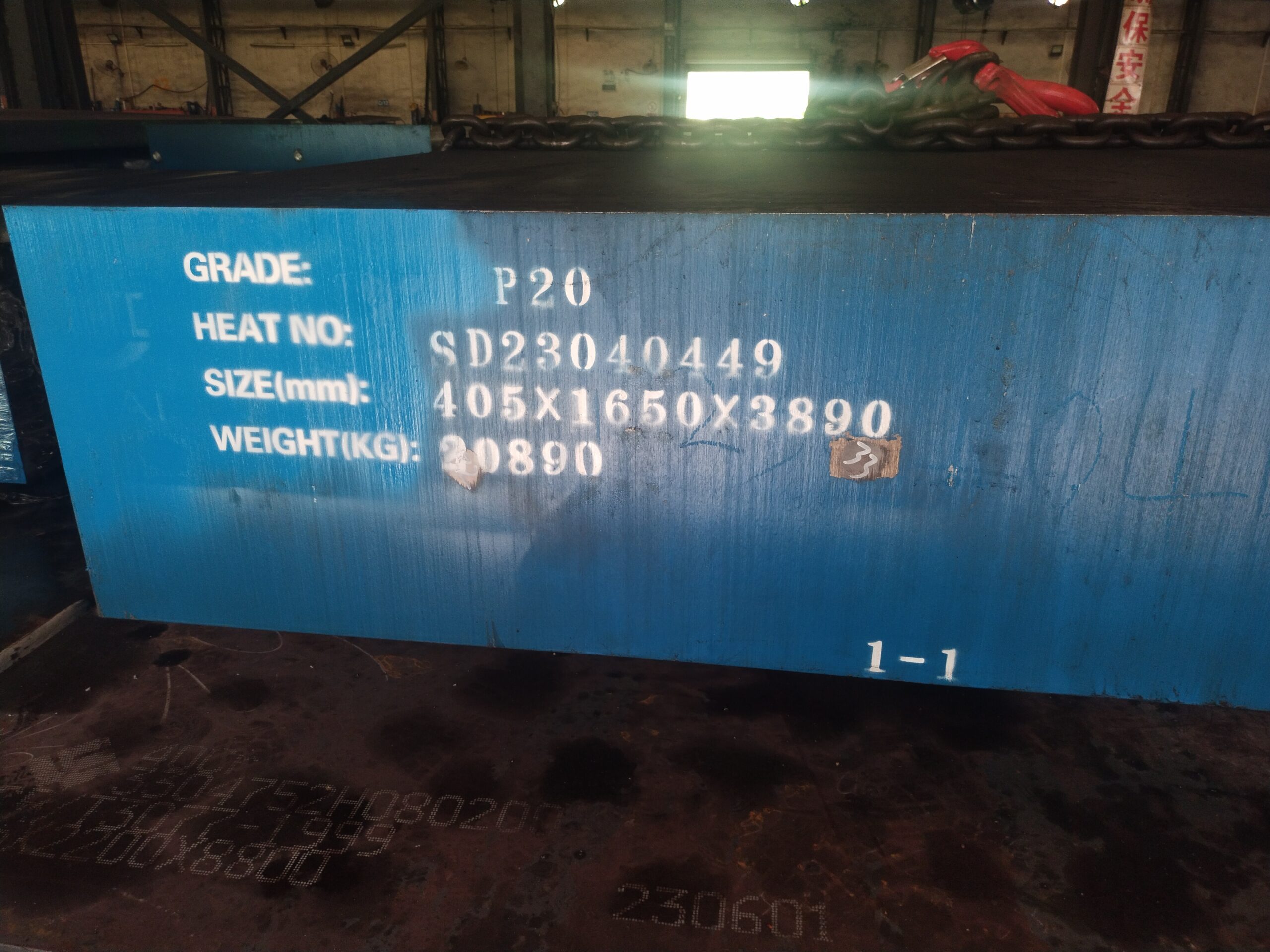

1.2311 steel, equivalent ASTM P20 steel.In contrast, 1.2738 steel, often referred to as P20+Ni steel, it easlier to find 1.2738 add 0.90%-1.20% Nickel base on 1.2311 , it means 1.2738 have a better strength than 1.2311.

Physical Properties 1.2311 VS 1.2738 steel :

Both steels have excellent machinability and polishability, therefore , both 1.2311 and 1.2738 steel are all suitable for mould making.

The little difference is the hardness between them. 1.2311 and 1.2738 steel both are pre-harden steel , but 1.2311 hardness is 28-34HRC , 1.2738 is 30-36HRC.

Mechanical Properties 1.2311 VS 1.2738 steel :

Mechanical Properties 1.2311 VS 1.2738 steel :

1.2311:

- Tensile Strength: 1050-1200 MPa.

- Yield Strength: 950-1100 MPa.

- Elongation: 15-20%.

1.2738:

- Tensile Strength: 1000-1150 MPa.

- Yield Strength: 900-1050 MPa.

- Elongation: 15-20%.

In summary, both 1.2311 and 1.2738 steel grades have similar tensile and yield strength along with comparable elongation properties, the key difference is their hardness, toughness, and impact resistance. 1.2311 steel offers good wear resistance and dimensional stability with slightly lower hardness, while 1.2738 steel provides improved toughness and impact resistance due to the addition of nickel, making it suitable for applications requiring enhanced mechanical properties under high-stress conditions.

Price compare :

Considering prices, 1.2311 steel is generally more cost-effective than 1.2738 steel due to differences in their chemical compositions . However, the overall cost may vary depending on factors such as market demand and supplier pricing.

Applications :

1.2311 Steel:

- Widely used for low to medium-volume production of plastic molds, particularly for injection molding applications.

- Suitable for making prototypes and master models due to its good machinability and polishability.

- Often employed in industries such as automotive, consumer goods, and electronics for producing various plastic components and parts.

- Ideal for applications where moderate mechanical strength and wear resistance are required, making it a cost-effective choice for molding applications with lower stress and impact requirements.

1.2738 Steel:

1.2738 Steel:

- Preferred for applications requiring higher toughness and impact resistance, especially in large-sized injection molds and tooling for automotive components.

- Well-suited for molds subjected to high-stress conditions and impact loads, such as those encountered in automotive and aerospace industries.

- Due to its enhanced toughness and resistance to deformation under high-stress conditions, 1.2738 steel is commonly used in applications where reliability and durability are paramount.

- Offers superior performance in applications where the mold is subjected to frequent loading and unloading, as well as in situations where molds need to withstand abrasive wear and prolonged use.

In summary, both 1.2311 and 1.2738 steel grades have their respective applications in mold making, the key difference lies in the specific requirements of the application. 1.2311 steel is suitable for low to medium-volume production with moderate mechanical strength requirements, whereas 1.2738 steel is preferred for applications demanding higher toughness and impact resistance, particularly in large-sized molds subjected to high-stress conditions.

Conclusion:

In summary, both 1.2311 and 1.2738 steels offer excellent properties for mould making applications, with slight differences in their chemical compositions, hardness levels, and prices. The choice between the two ultimately depends on specific project requirements, budget considerations, and desired performance characteristics.

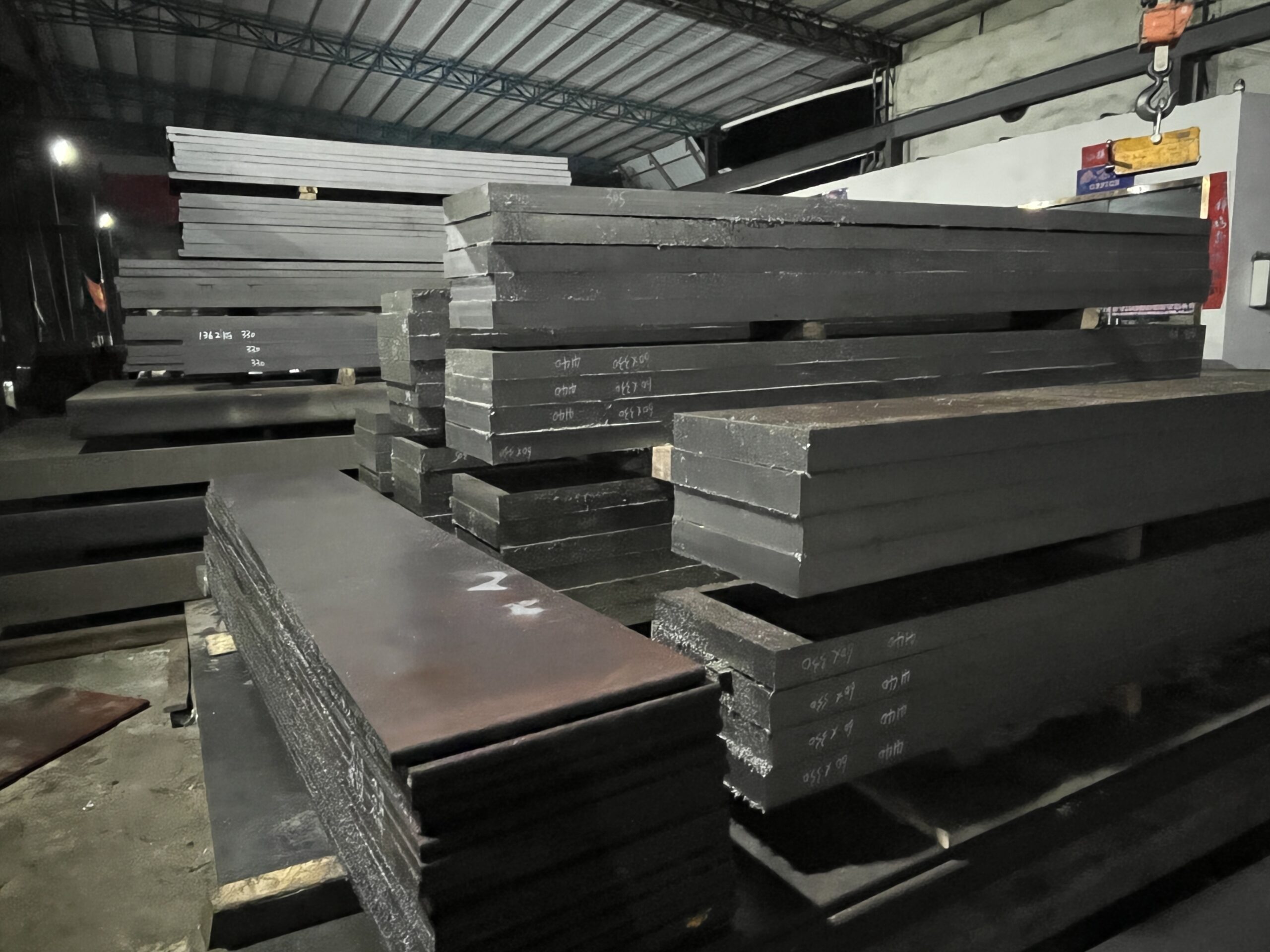

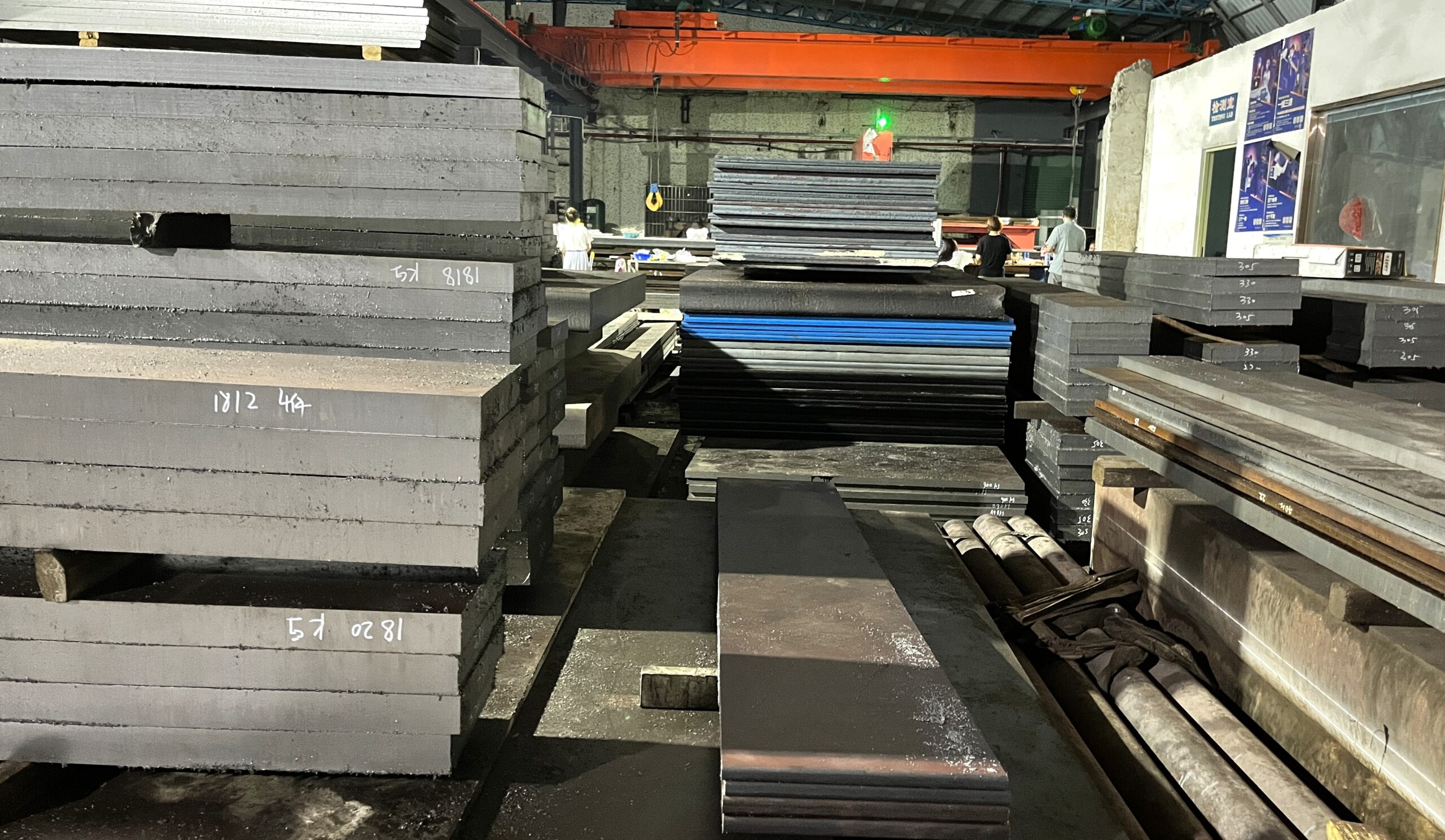

Otai special steel stock compelete size of 1.2311, 1.2738 steel, if there is any interest ,please contact below information to get the stock list.

S136 steel is chromium-nickel-molybdenum-vanadium alloy steel. As a high-quality plastic mold steel, S136 is widely used in injection molds, extrusion molds, blow molds and other fields. This mold steel has excellent corrosion resistance, polishability, wear resistance, and machinability, making it an ideal choice for manufacturing high-quality, high-precision plastic products.

S136 steel is chromium-nickel-molybdenum-vanadium alloy steel. As a high-quality plastic mold steel, S136 is widely used in injection molds, extrusion molds, blow molds and other fields. This mold steel has excellent corrosion resistance, polishability, wear resistance, and machinability, making it an ideal choice for manufacturing high-quality, high-precision plastic products.

P20 Steel application

P20 Steel application Name: Joann

Name: Joann

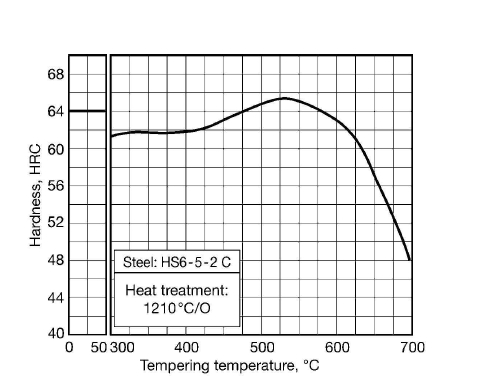

Heat treatment about DIN 1.3343 steel

Heat treatment about DIN 1.3343 steel

Due to its high strength, toughness, and weldability. It finds applications in various industries, including:

Due to its high strength, toughness, and weldability. It finds applications in various industries, including:

Application:

Application: Application:

Application:

Physical Properties of 36CrNiMo4 Steels

Physical Properties of 36CrNiMo4 Steels

Annealing

Annealing

Application:

Application:

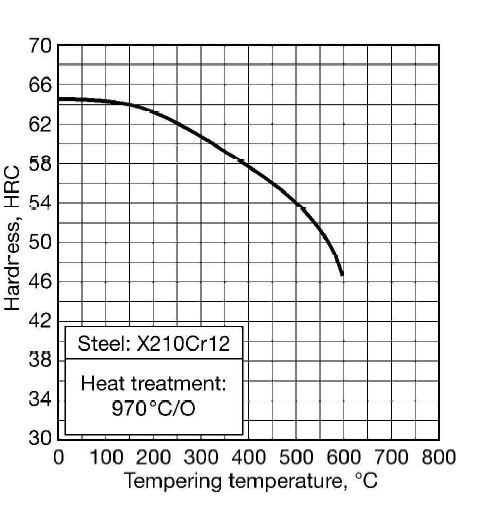

DIN 1.2436 Physical Properties:

DIN 1.2436 Physical Properties: FAQs about 1.2436 Steel

FAQs about 1.2436 Steel