When it comes to heavy-duty industries like construction, mining, and manufacturing, the choice of materials plays a pivotal role in determining the success and longevity of the equipment used. Two prominent names that often surface in discussions about wear-resistant steel are NM500 and Hardox500. In this exploration, we delve into the characteristics, applications, and nuances that differentiate these stalwarts in the steel domain.

Understanding NM500

NM500 is a high-strength wear-resistant steel known for its robustness and durability. Developed to withstand abrasive conditions, NM500 is often the material of choice for machinery exposed to extreme wear and tear. It belongs to the family of abrasion-resistant steels, specifically designed to endure harsh working environments.

Composition of NM500

The composition of NM500 typically includes a combination of iron, carbon, manganese, chromium, and other alloying elements. This intricate blend imparts exceptional hardness and toughness to the steel, making it adept at resisting abrasion.

| C | Si | Mn | P | S | Cr | Ni | Mo | Ti | |

| Max | |||||||||

| NM500 | 0.38 | 0.70 | 1.70 | 0.020 | 0.010 | 1.50 | 1.00 | 0.65 | 0.050 |

Applications of NM500

Applications of NM500

Due to its superior wear resistance, NM500 finds applications in a myriad of industries. From earthmoving equipment in construction to mining machinery, NM500 is the unsung hero that prolongs the life of these heavy-duty tools. Its resilience in the face of abrasive materials makes it a reliable choice for components subjected to constant friction.

Decoding Hardox500

Hardox 500, a flagship product from the renowned Swedish steel manufacturer SSAB, is another heavyweight contender in the wear-resistant steel arena. Engineered for toughness and wear resistance, Hardox 500 has carved its niche as a premium choice for industries demanding uncompromising reliability.

Chemical Makeup of Hardox500

Hardox 500 boasts a sophisticated composition, comprising iron, carbon, manganese, and chromium, among other alloying elements. This carefully crafted blend results in a steel variant with exceptional hardness, making it resistant to wear and impact.

| C | Si | Mn | P | S | Cr | Ni | Mo | B | |

| Max | |||||||||

| Hardox500 Sheet | 0.27 | 0.50 | 1.60 | 0.025 | 0.010 | 1.20 | 0.25 | 0.25 | 0.005 |

| Hardox500 Plate | 0.30 | 0.40 | 1.30 | 0.020 | 0.010 | 2.20 | 2.00 | 0.40 | 0.005 |

Applications of Hardox500

Hardox 500 is celebrated for its versatility, finding applications in diverse sectors such as construction, agriculture, and mining. Its ability to withstand extreme conditions without succumbing to wear makes it an ideal material for components like buckets, blades, and other wear-prone parts of heavy machinery.

Comparing NM500 and Hardox500

Now that we’ve acquainted ourselves with the individual strengths of NM500 and Hardox 500, let’s embark on a comparative journey to unearth the distinctions that set them apart.

Hardness and Toughness of NM500 and Hardox500

One of the primary differentiators between NM500 and Hardox 500 lies in their hardness and toughness. While both steels are engineered to resist wear, the nuances in their composition contribute to variations in these aspects. NM500, known for its high hardness, excels in scenarios where abrasive forces are a constant challenge. On the other hand, Hardox 500 strikes a balance between hardness and toughness, making it resilient not only to abrasion but also to impact.

Weldability and Formability about NM500 and Hardox500

In the realm of weldability and formability, Hardox 500 often takes the lead. Its composition allows for easier welding without compromising its inherent toughness. NM500, while robust, may pose challenges during welding processes. The choice between the two may depend on the specific requirements of the application and the welding methods employed.

Cost Considerations

Cost is a pivotal factor in any industrial decision, and the choice between NM500 and Hardox 500 is no exception. NM500, often regarded as a more economical option, provides substantial wear resistance at a relatively lower cost. Hardox 500, being a premium product, comes with a higher price tag but compensates with enhanced performance in certain applications.

Weight and Structural Considerations

In applications where weight is a critical factor, NM500’s higher hardness might be advantageous. The reduced need for material thickness can contribute to lighter components without compromising wear resistance. However, for applications where a balance between weight and toughness is crucial, Hardox 500 may emerge as the preferred choice.

Conclusion about NM500 and Hardox500

In the tug-of-war between NM500 and Hardox 500, the choice ultimately boils down to the specific demands of the application. NM500, with its high hardness, is a stalwart against abrasion, while Hardox 500, with its balanced toughness, conquers challenges that involve both wear and impact. Weldability, formability, cost, and weight considerations further guide the decision-making process. As industries evolve, the need for robust materials like NM500 and Hardox 500 continues to grow, each steel variant leaving an indelible mark in the landscape of wear-resistant solutions.

FAQs About NM500 and Hardox500

FAQs About NM500 and Hardox500

1. Can NM500 and Hardox 500 be used interchangeably in all applications?

– While both steels exhibit remarkable wear resistance, the choice should align with the specific demands of the application. Factors such as hardness, toughness, and cost considerations play a crucial role in the decision-making process.

2. Are there any notable differences in the welding processes for NM500 and Hardox 500?

– Yes, there are differences in the weldability of these steels. Hardox 500 generally offers better weldability, making it a preferred choice in applications where welding is a critical factor.

3. What industries benefit the most from the unique properties of NM500 and Hardox 500?

– NM500 and Hardox500 find applications in a range of industries, including construction, mining, agriculture, and manufacturing. Their wear-resistant properties make them indispensable in equipment subjected to abrasive conditions.

4. How do cost considerations impact the choice between NM500 and Hardox 500?

– NM500 is often considered a more economical option, providing substantial wear resistance at a relatively lower cost. Hardox 500, being a premium product, comes with a higher price tag but compensates with enhanced performance in certain applications.

5. Can these steels be used in environments with extreme temperatures?

– Both NM500 and Hardox 500 are designed to withstand harsh conditions, ut prolonged exposure to extreme temperatures can affect their performance. It’s advisable to consult with experts to determine the suitability of these steels for specific temperature-sensitive applications.

Want to know more about the details ?

Pls contact : Joann

E-mail:joann@otaisteel.com

WhatsApp:+8613128068365

Versatility in Applications

Versatility in Applications

FAQs

FAQs

Sharper Than the Rest

Sharper Than the Rest Heat Treatment: Unleashing the Full Potential

Heat Treatment: Unleashing the Full Potential

Excellent Toughness at High Temperatures

Excellent Toughness at High Temperatures Tooling and Molds

Tooling and Molds FAQs

FAQs

The Role of H13 Steel in the Automotive Industry

The Role of H13 Steel in the Automotive Industry Challenges and Solutions in Working with H13 Steel

Challenges and Solutions in Working with H13 Steel 2. How does H13 steel contribute to environmental sustainability?

2. How does H13 steel contribute to environmental sustainability?

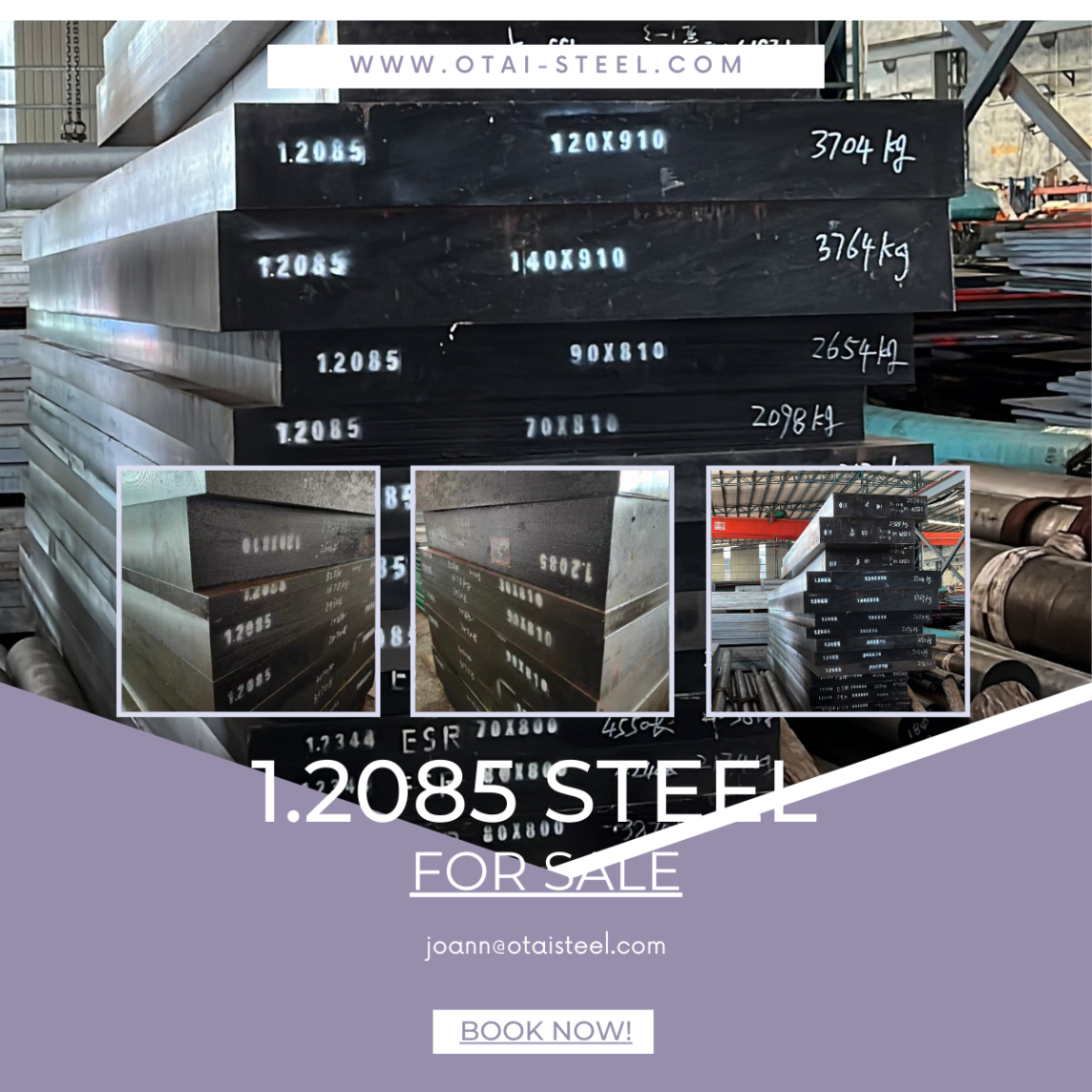

2. Properties of 1.2085 Steel

2. Properties of 1.2085 Steel 4. 1.2085 Steel Equivalents

4. 1.2085 Steel Equivalents

4140 and 52100 both are widely used steel , they are often compared and evaluated for their suitability in various applications. In this article, we’ll explore the characteristics, properties, and applications of these two steel types, highlighting their differences and unique features.

4140 and 52100 both are widely used steel , they are often compared and evaluated for their suitability in various applications. In this article, we’ll explore the characteristics, properties, and applications of these two steel types, highlighting their differences and unique features. Key Differences

Key Differences